Operational

Review

FUTUREPROOFING OUR OPERATIONS

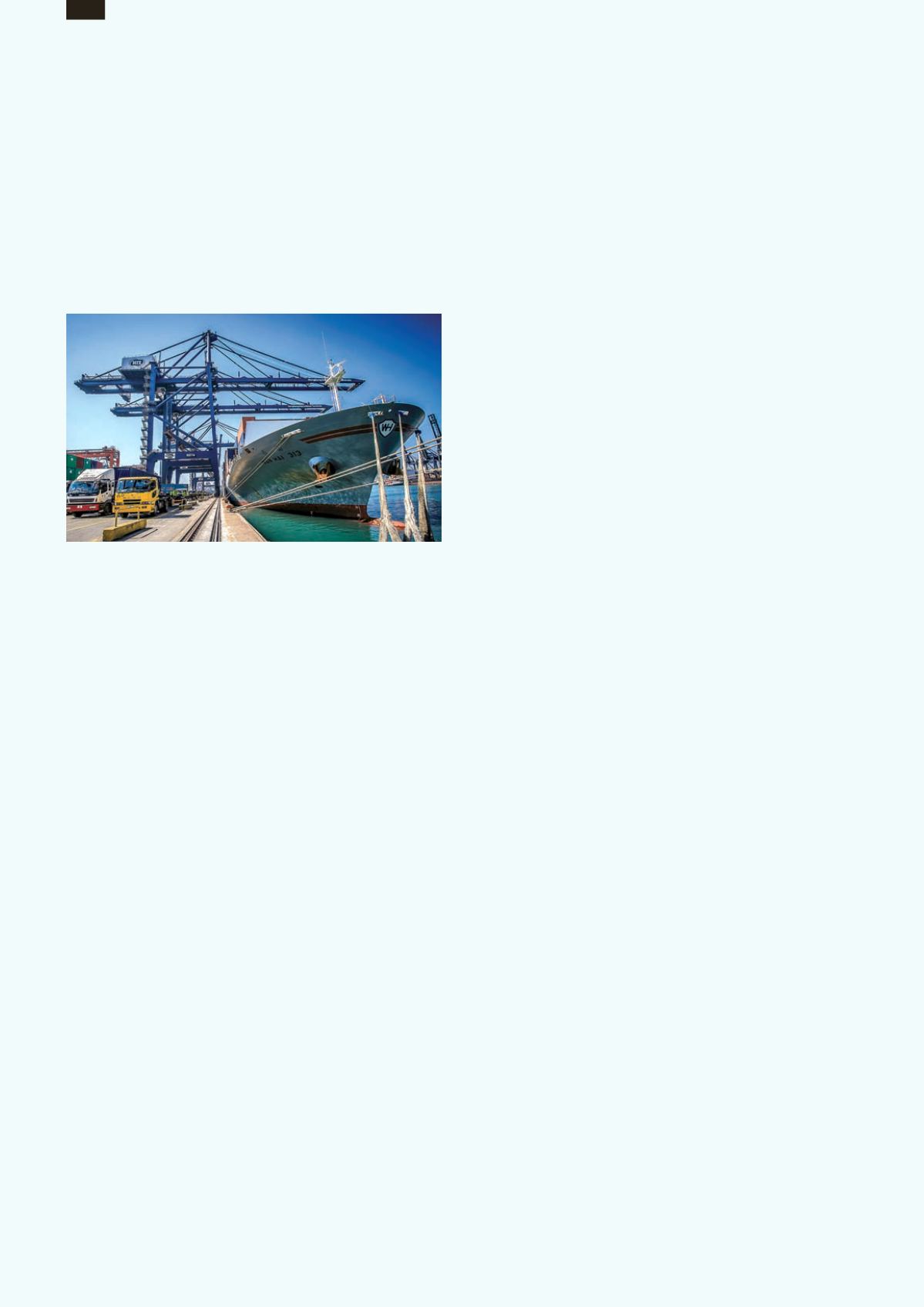

Despite softening market conditions and economic uncertainties,

the Trust was able to deliver on major growth targets and

proactively took measures in light of new challenges, changing

customer demands and increasing stringent environmental and

safety regulations.

Trust-wide asset enhancement over the years resulted in numerous

operational accomplishments in 2015, most significant of which

were the Trust’s Hong Kong operations achieving its 200 millionth

TEU and YICT receiving four mega-vessels simultaneously for

the first time in June. Simultaneously servicing three 18,000-plus

TEU container vessels, along with one 11,000-plus TEU vessel

concurrently, was a testament to YICT’s superior mega-vessel

handling capabilities in the region.

At the core of this was a significant push to further increase

operational productivity and eciency, and to encourage

innovation in a way that enables the Trust to enter into new cycles

of progress and value creation. Vigorous steps in the form of

expansion plans, investments in new technologies and equipment,

process improvement, training, as well as enhancements to the

work environment were undertaken in 2015.

These initiatives laid the groundwork for stable full year results

reflective of the Trust’s solid fundamentals, foresight, adaptability

and resilience. Although full year throughput dipped slightly, cost

and tari improvements helped deliver an increase in operating

profit. To continue safeguarding the interests of its unitholders,

partners and employees, the Trust embarked on a drive to

futureproof its assets: its Ports, People and Processes.

PORTS, PEOPLE, PROCESSES

In line with the strategy of “Optimising for the Future”, the

Trust has committed to a HK$1.8 billion equipment investment

plan to acquire or upgrade its assets to facilitate long-term

development. New plans were also put in place to modernise

port infrastructure, augment handling capacities and

capabilities. Initiatives included, but are not limited to the

installation of mega QCs, RTGCs and purpose-built barge QCs.

In 2015, YICT welcomed four new QCs. With a higher lift height

of 52 metres and a longer outreach of 70 metres, each of the

new QCs serve to accommodate the increasing number of

mega-vessels around the world. To enhance its yard stacking

capacity and container handling eciency, YICT also received

22 1-over-6 RTGCs that can stack up to six tiers of containers. In

Hong Kong, HIT took delivery of two new QCs with lift height of

46 metres and 12 1-over-6 electric RTGCs.

As part of an ongoing review of its operations, the Trust

launched the BOXplus Building Operations Excellence project

in February 2015. This 40-week eciency enhancement

programme focused on reducing vessel turn around time by

7-10%. To achieve this goal, a cross-functional team worked to

streamline operations, enhance handling capabilities, optimise

resource utilisation, reduce crane-maintenance related

downtime and improve customer service.

This pilot project, supported by the operations, engineering and

commercial departments of HIT, concluded with significant

improvements in berth productivity and accuracy of estimated

time of vessel departure while reducing operational delays

and preventive maintenance related downtime. These results

translated to savings in cost of services, particularly during

the third and fourth quarters. Lessons from this project will be

brought to scale and applied across the Trust’s other assets to

ensure best practices are replicated.

In 2015, HIT conducted a trial run of remote-controlled

RTGCs. These cranes are operated remotely from an oce

environment, improving operator comfort and workplace safety.

Technologies utilised in this project include high speed data

transmission networks, leading Radio Frequency Identification

(“RFID”), optical recognition, and cameras that deliver live

videos. After extensive testing, four remote-controlled RTGCs

were successfully deployed at HIT’s Container Terminal 9.

Following the completion of this trial, HIT will convert another 25

of its conventional RTGCs to remote-controlled RTGCs. Trucks

will be equipped with RFID to enable automatic identification

as they pass through dierent checkpoints inside the terminal.

These initiatives will support the Trust’s goal of improving

operational eciency, industrial safety and providing an

improved working environment.

In 2015, the Trust continued to use technology to help centralise

control, improve berth and yard utilisation and oer real time

feedback necessary for quicker response. Critical investment

was made in the area of communications, where it adopted 3G

internal tractor pagers as a next step to strengthening in-yard

wireless signal reception capabilities and lowering internal

tractor turnaround times.

Similarly, automation has become the backbone in

revolutionising port management. With an annual throughput

of over 12 million TEUs, the location and eciency of YICT’s

OPTIMISING FOR THE FUTURE

032